This post lets you know that this is the test site. You have successfully edited your hosts file!

Category: Uncategorized

How Washington became a global epicenter for advanced carbon fiber

Stronger than steel and lighter than aluminum, carbon fiber materials are one of the key enabling technologies of the 21st century. They play an especially important role in Washington, the world leader in carbon fiber composite manufacturing. Just as silicon is the material that underlies the innovation ecosystem of Silicon Valley, so carbon fiber is to the state of Washington.

See article (link is below under read more) by Andy Freeberg, UW ME Communications Manager.

ACC researchers wins Best of BTEC Awards

Advanced Composites Center (ACC) researchers have won the Best of BTEC award for two consecutive years at the Boeing Technical Excellence Conference where hundreds of the Boeing company’s engineers gather each year to discuss innovations.

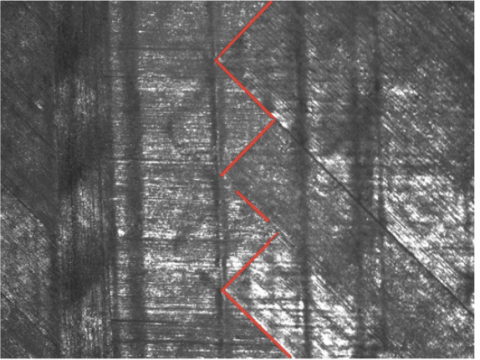

The 2019 Best of BTEC award went to the work on “Improved Tow-End Recognition for Fiber Placement Inspection using Machine Learning ” by Wei Guo, Ekta Samani, Ashis Banerjee, Sophie O’Neill, Lukas Wavrin, Stacy Harting, John Stewart and Agnes Blom-Schieber.

For additional information see Data Science for Manufacturing.

The 2020 Best of BTEC award in Manufacturing, Materials & Safety went to the work on “Mechanically actuated pneumatic avatar for out-of-tank teleoperated control” by Ben Wong, Kyle Schultz, Lucky Singh, Derek Loy, Wade Marquette, Santosh Devasia, Joe Garbini, Shuonan Dong, Jerry Chungbin, John Fuller, and Sam Pedigo

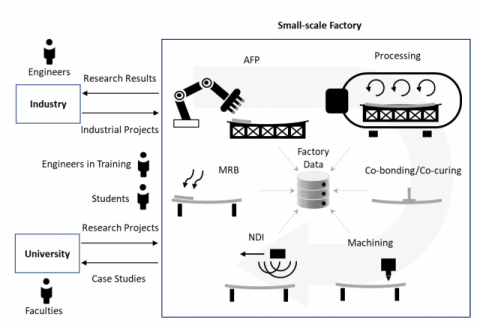

A Factory-Centric Workforce Development Approach for Aerospace Industry

Navid Zobeiry presented A Factory-Centric Workforce Development Approach for Aerospace Industry through the SAMPE Virtual Series. Given the rapid transformation of the aerospace sector in the last decade, teaching practices should prepare engineers to face fast-paced industries that are dealing with exceedingly complex problems. Now more than ever we need engineers who are capable of working and communicating effectively within large and multi-disciplinary groups, considering the introduction of new material systems such as advanced composites in primary structural elements, development of automated processing methods such as Automated Fiber Placement (AFP), and the transition to interconnectivity among production systems, workers, products and customers. Exceedingly we need to train well-rounded and practical-minded engineers and scientists. At the University of Washington, we are dedicated to support the aerospace industry by training the next generation of engineers. A new 16,000 sq. ft. facility, Advanced Composites Center (ACC), will be dedicated for the manufacturing of aerospace composite parts. Taking advantage of automation and AFP processing, sensor technologies, autoclaves and other manufacturing equipment, we aim to replicate a small factory within the university environment at the ACC. Partnering with industry, this facility will enable students to gain practical experience working on industry-relevant problems within a factory setting. In addition, while working on industrial projects, students will gain experience on business, intellectual property (IP) and project management aspects.

A pdf of the article can be found at paper preprint.

Citation: Zobeiry N., Seaton C., Salviato M., Chen X., Banerjee A., Devasia S., Yang J., Blom-Schieber A., Buttrick J., Pedigo S., (2020). A factory-centric workforce development approach for aerospace industry, SAMPE 2020 Virtual Series, Society for the Advancement of Material and Process Engineering, Seattle, WA

A video of the presentation is available from SAMPE 2020 Virtual Series below.

https://www.youtube.com/embed/BI66zylm-nQ?si=aboYj0egu3qzkxtF

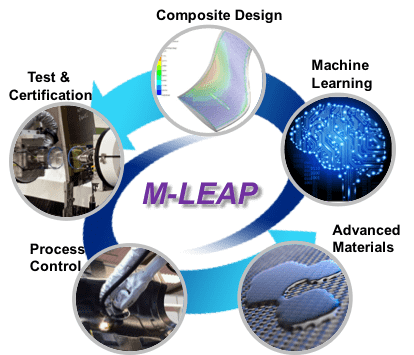

ACC awarded $1.2 million to advance composites

Clean Energy Funds

UW has received $1.2 million from the Washington State Department of Commerce’s Energy Research, Development & Demonstration Program’s Clean Energy Fund to help launch the Advanced Composites Center (ACC) . The project is one of ten selected this year out of 52 total applicants.

The award – along with additional funding from industry and the UW – helps to lay the groundwork for the new Advanced Composites Center, which brings together composites manufacturing research projects and educational efforts.

This new center will allow UW researchers to advance their work to make composites manufacturing economically viable by ensuring better quality, lower energy costs, and waste and scrap minimization. Specifically, the team’s project will demonstrate how to predictably design and produce complex thermoplastic composite parts using automated robotic systems.